In Detail

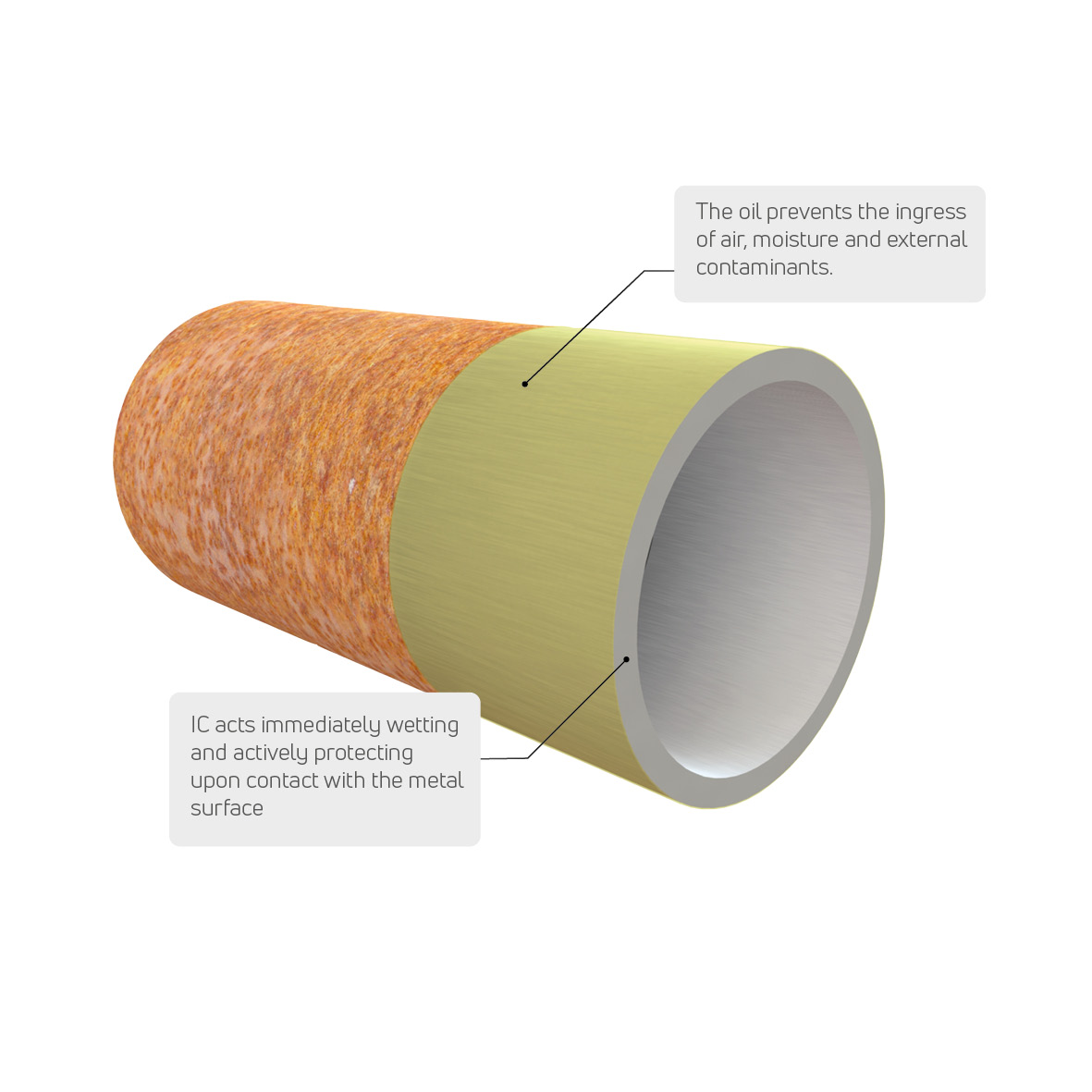

Inhibitor coating is an oil based liquid which lubricates and actively displaces moisture replacing with a protective barrier.

IC creates a film which is not easily washed away, both versions have slightly different finished properties:

- IC200 stays as a liquid residue after application and can be removed with a surfactant

- IC500 forms a semi-solid membrane finish and can be removed with a degreaser

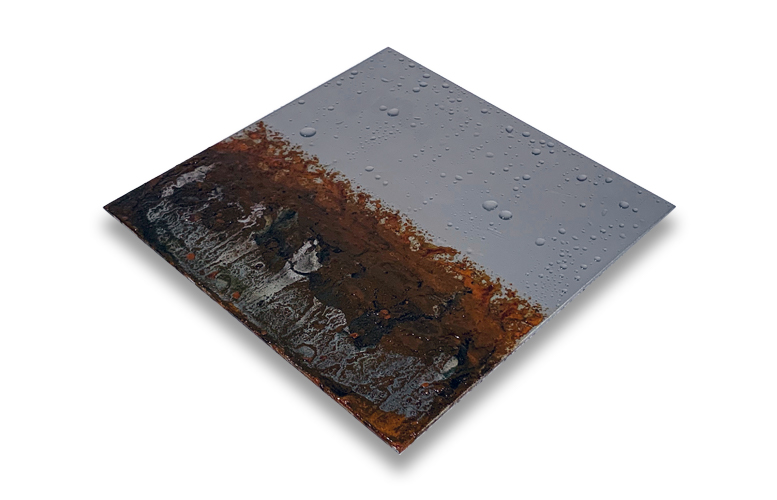

Both products are applied by a brush, working the non-solvent oil into the contours and crevices of any asset. It spreads with application and the oil will penetrate any existing corrosion and displace any moisture.

Surface preparation simply requires brushing away any loose debris, equipment can remain in operation saving both time and money.

“Essentially IC200/500 are taking the inhibitor oil element out of TM198 and varying its formulation to use as stand-alone, short-term solutions.” Ed Notley, Technical Manager.

IC200 and IC500 are non-flammable and solvent free.